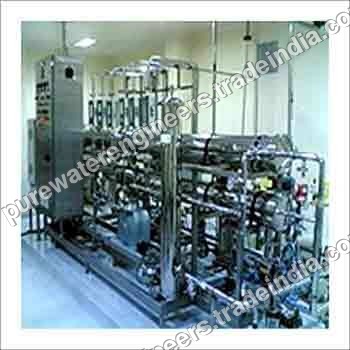

Post ETP RO Plant

Price 50000-2000000 INR/ Plant

Post ETP RO Plant Specification

- Automatic Grade

- Full Automatic

- Water Source

- Ground Water

- Drive Type

- Electric

- Material

- Stainless Steel

- Product Type

- Purified Water Generation System

Post ETP RO Plant Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 1 Plant Per Month

- Delivery Time

- 1 Months

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About Post ETP RO Plant

Advanced Stainless Steel Construction

Built entirely from high-quality stainless steel, this RO plant guarantees longevity and resistance against corrosion. Its robust design makes it suitable for challenging environments, ensuring pure water output for years to come. The use of stainless steel also means easier maintenance and hygiene management, critical for water treatment applications.

Automatic Operation for Hassle-Free Water Treatment

Featuring a fully automatic system driven by electric power, the RO plant minimizes manual involvement. Users can benefit from automatic monitoring and controls, reducing operational errors and optimizing efficiency. The automation enhances consistent water quality, catering efficiently to various storage capacities from 500 up to 20,000 liters.

FAQs of Post ETP RO Plant:

Q: How does a Post ETP RO Plant function in treating groundwater?

A: The Post ETP RO Plant operates by filtering treated water from an effluent treatment plant (ETP) through a reverse osmosis membrane. This process removes dissolved solids, contaminants, and pathogens, producing high-quality, purified water suitable for various applications.Q: What are the benefits of using stainless steel in the RO plants construction?

A: Stainless steel offers exceptional durability, resistance to corrosion, and easy cleaning, which are essential for water treatment. It also ensures the plant maintains hygiene standards and extends the lifespan of the equipment, especially in demanding operational environments.Q: When is this RO plant most beneficial to use?

A: This plant is particularly useful after effluent treatment, when further purification of groundwater is required for reuse or safe discharge. Its ideal for industrial and commercial settings where large volumes of purified water are needed on a daily basis.Q: Where is the Post ETP RO Plant typically installed?

A: It is commonly installed in industries, commercial complexes, and large residential societies across India that require large-scale water purification solutions. Its flexibility in storage capacity enables customization to meet specific site requirements.Q: What processes are involved in the RO plants water purification?

A: The primary process involves reverse osmosis, where water is forced through semi-permeable membranes that remove dissolved salts, heavy metals, and contaminants. Pre and post-filtration stages may also be included to enhance final water quality and membrane longevity.Q: How is the plant operated and monitored for optimal performance?

A: The fully automatic design ensures the plant operates with minimal manual intervention. Advanced control panels enable real-time monitoring of parameters such as flow rate, pressure, and water quality, ensuring consistent performance and prompt alerts in case of anomalies.Q: What are the main advantages of sourcing this RO plant from an Indian manufacturer, exporter, or supplier?

A: Indian manufacturers offer cost-effective solutions with robust after-sales support, customized configurations, and adherence to international quality standards. Exporters and suppliers in India ensure timely delivery and comprehensive servicing, making them reliable partners for water treatment needs globally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Purified Water Generation systems Category

Pure Water Generation Systems

Price 50000-2000000 INR / Plant

Minimum Order Quantity : 1 Plant

Automatic Grade : Semi Automatic

Drive Type : Electric

Product Type : Water Generation Systems

Power Source : Electric

Reverse Osmosis Plants

Minimum Order Quantity : 1 Plant

Automatic Grade : Semi Automatic

Drive Type : Electric

Product Type : Reverse Osmosis Plants

Power Source : Electric

Ultra Filtration (UF) Systems

Price 50000-2000000 INR / Plant

Minimum Order Quantity : 1 Plant

Automatic Grade : Full Automatic

Drive Type : Electric

Product Type : Water Filter

Power Source : Electric

EDI - Electro De ionization Systems

Price 50000-2000000 INR / Plant

Minimum Order Quantity : 1 Plant

Automatic Grade : Full Automatic

Drive Type : Electric

Product Type : Purified Water generation System

Power Source : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free